Products

Featured products

Contact Us

Description:

At present, the anodes used in the electrolysis industry are mostly lead anodes, with a small portion using iridium titanium anodes. Lead anodes have high energy consumption and significant pollution, and have gradually withdrawn from the electrolysis industry. Iridium titanium anodes are not accepted by the market due to their high price. Therefore, a new type of anode, titanium based lead dioxide anode, is currently being promoted and used in the electrolysis industry in China, and the results are quite satisfactory. The following is a brief introduction to this type of anode.

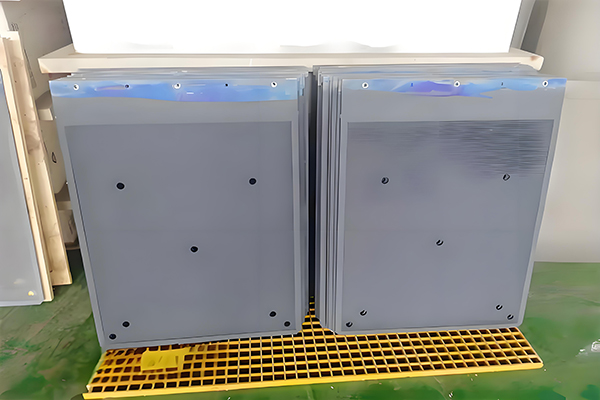

Introduction to titanium based lead dioxide titanium anode for wet metallurgy

1. Application areas: Electrodeposited copper, nickel, cobalt, zinc and other non-ferrous metals

2. Product specifications: Processing according to drawings

3. Anode lifespan: Over 2 years

4. Coating type: Titanium based lead dioxide anode

5. Comparison between titanium based lead dioxide anode and traditional lead anode:

The whole tank test work of the production system has shown the following advantages:

A. No pollution to the electrolyte, no need for complex lead removal system expenses.

B. The external dimensions are fixed and will not cause anode deformation due to self dissolution, which will affect the cathode product phase.

C. The titanium substrate can be reused.

D. High current efficiency.

E. The slot voltage is low.

F. The quality of cathode products is high.

G. It can operate at high currents, and lead anodes dissolve quickly under high currents. Titanium based lead dioxide anodes can withstand currents of over 500A/m2, making them suitable for short-term high output requirements in production.

H. Reduce labor intensity and improve working environment.