Products

Featured products

Contact Us

Significant achievements have been made in the research and development, complete supply, and technical services of non-standard equipment for non-ferrous smelting (especially copper, nickel, and cobalt smelting).

Copper electrolysis equipment

1、 Key equipment

Unit type:

1. Copper electrolysis specialized lifting equipment

Copper electrolysis automatic crane and lifting equipment; Automatic crane with 2mm high-precision positioning; Specialized vehicle;

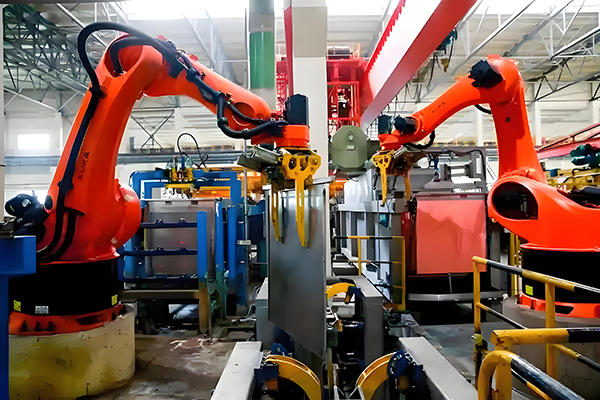

2. Robot cathode stripping unit

Arrange distance devices; Transport trolley device; Washing system; Rapid air drying; Cathode stripping device; Cathode plate verticality detection device; Cathode copper plate conveying, palletizing, and packaging device;

3. Residual washing unit

Automatic cleaning system; Stacking device; Fully enclosed flipping structure;

4. Anode shaping unit

Anode copper; Anode plate conveying mechanism; Plastic surgery machine; Correct headphones; Milling earphones; Anode plate discharge machine; High speed milling technology; Horizontal transport vehicle;

5. Permanent stainless steel cathode plate

316L stainless steel plate; Conductive rod; Insulation clip edge strip;

Keywords related to copper electrolysis:

Copper; Electrolytic refined copper; Stainless steel cathode electrolysis; Permanent cathodic electrolysis method; Permanent stainless steel cathode plate; Electrolyte; Nickel sulfate; Circulating water; Fiberglass inner tank electrolytic cell;

2、 Key parameters:

Key parameters of robot cathode stripping unit:

Equipment form: Robot peeler

Number of single slot cathode plates: 55 pieces/slot

Cathode plate specification: 1050mmx1016mm

Distance between cathode plates: 100mm

Cathode plate stripping capacity: 200-600 pieces/hour

Stainless steel cathode plate unit weight: 45kg/piece

Electrolyte composition: Cu2+: 45-50g/l; fH2SO4:180~200g/l; CL-:<0.1g/l

Control mode: PLC

Noise level: Noise level below 85dB (A) at a distance of 1 meter from the device

(Robot cathode stripping unit) Product application:

Automatic scheduling, transportation, washing, peeling of cathode plates in copper electrolysis workshop, stacking of cathode copper, packaging and conveying of steel strips.

(Robot cathode stripping unit) Product features:

1. Thoroughly clean, quickly air dry, and leave no residual electrolyte.

2. Peel capacity>600 pieces/hour, smooth and noiseless dropping of pieces.

3. Flex pre stripping, flip stripping, and impact stripping are integrated without damaging the electrode plate.

4. Automatic palletizing, packaging, and conveying.

5. Automatically identify obstacles, low failure rate, and high safety.

(Copper electrolysis specialized lifting equipment) Product application:

Automatic removal and installation of anode and cathode plates in the copper electrolysis workshop for electrolytic cell operations.

(Copper electrolysis special lifting equipment) Product features:

1. Unique insulation protection technology

2. Automatic crane with 2mm high-precision positioning

3. High level anti sway and anti magnetism

4. Remote diagnosis and maintenance system

5. Infrared short circuit detection of electrolytic cell

(Anode shaping unit) Product application:

Automatic shaping, testing, scheduling, and transportation of anode plates in copper electrolysis workshop.

(Anode shaping unit) Product features:

1. Nine point flattening type pressing device

2. Efficient, parallel arrangement of side milling device and bottom milling device

3. Stepped beam structure replaces chain conveyor

(Residual pole washing unit) Product application:

Automatic cleaning, rapid air drying, stacking, packaging, and transportation of residual plates in the copper electrolysis workshop.

(Residual pole washing unit) Product features:

1. Continuous operation capacity ≥ 400 pieces/h, stable performance

2. Good washing effect, no anode mud or electrolyte residue on the electrode plate

3. Automatic flushing, air drying, stacking and transportation with low failure rate

4. Fully enclosed flip structure to meet the washing requirements of different residual electrode plates

(Permanent stainless steel cathode plate) Product application:

Cathodic conductivity and copper precipitation in copper electrolysis workshop.

(Permanent stainless steel cathode plate) Product features:

1. Excellent conductivity

2. Service life exceeding 15 years

3. Annual replacement rate less than 10%

4. The service life of the edge strip is greater than 2 years